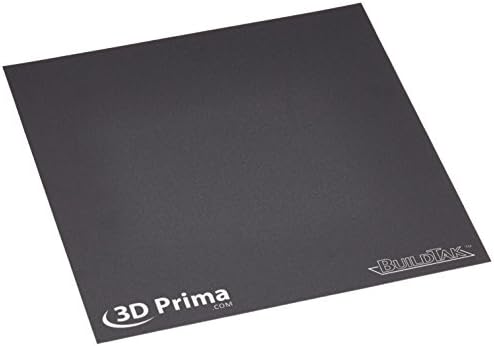

Buildtak Adhesion Mat

235x235mm 310x310mm mats can be cut down to fit smaller bed sizes works with all major filament types pla petg abs pc asa tpe tpu nylon may need glue to hold down completely as well as an enclosure 0 6mm thick for durability and longevity can be installed directly on the bed or glass.

Buildtak adhesion mat. Start from one edge of the build plate and work your way to the other edge smoothing the buildtak sheet with a credit card or. It comes as a sheet with an adhesive back. In addition the flexplate system makes utilizing buildtak sheets even easier. Sticks well even at 100 c build plate temp.

Remove the white adhesive liner and apply the buildtak sheet to the bare build plate. Buildtak is a popular all purpose 3d bed surface. As my tests with abs have shown even buildtak does not generate enough adhesion to print this material without a heated bed. My sheets last for hundreds of prints as long as you are gentle with the removal.

Dont drive a hot extruder tip into it though or it ll melt. Wipe down your bare build platform making sure it is clean and free of debris. Simply peel the protective film off and then stick it to your bed. Trim the buildtak sheet to match the size of your build plate if not already.

Ideal jacobs corp 2020. Available in many sizes to fit all kinds of 3d printers simply add the magnetic. Proprietary polycarbonate blend build sheet w genuine 3m adhesive available sizes. It is not an alternative to a heated print bed.

Takes the hassle out of build plate adhesion. The limitations of buildtak.