Boron Nitride Ceramic Heater

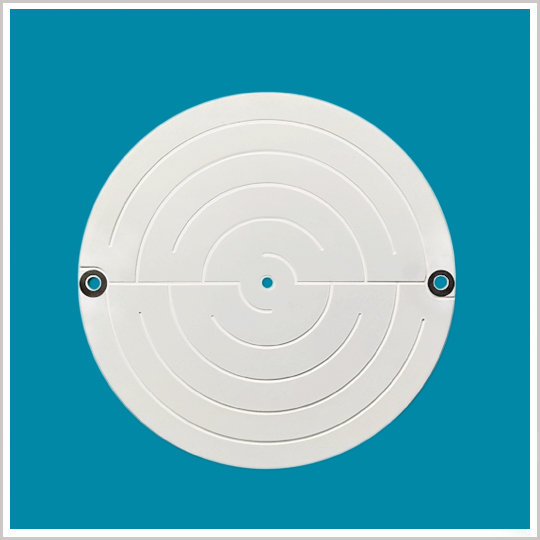

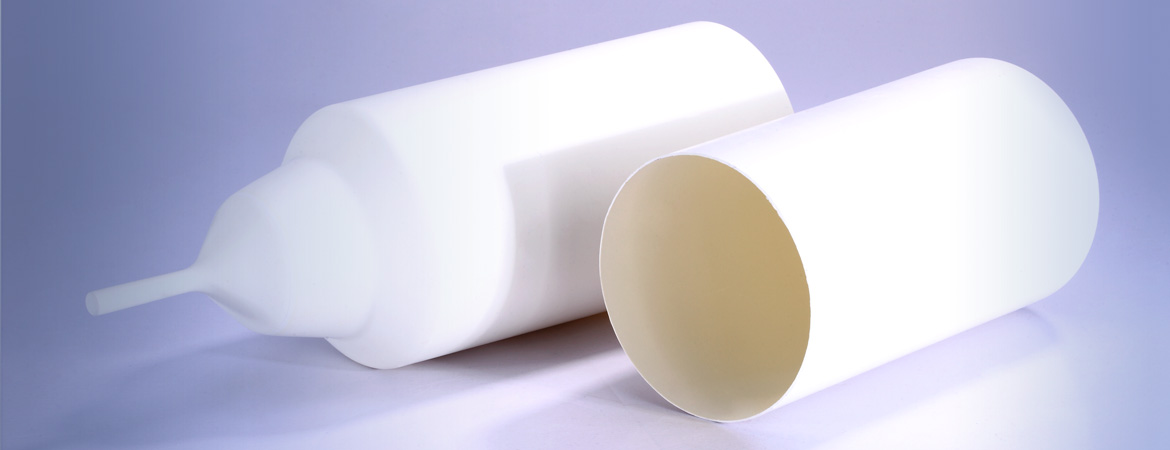

The pbn pg ceramic heater combines three layers of ultra high purity ceramics pbn pg pbn to produce an advanced micro ceramic heating element system.

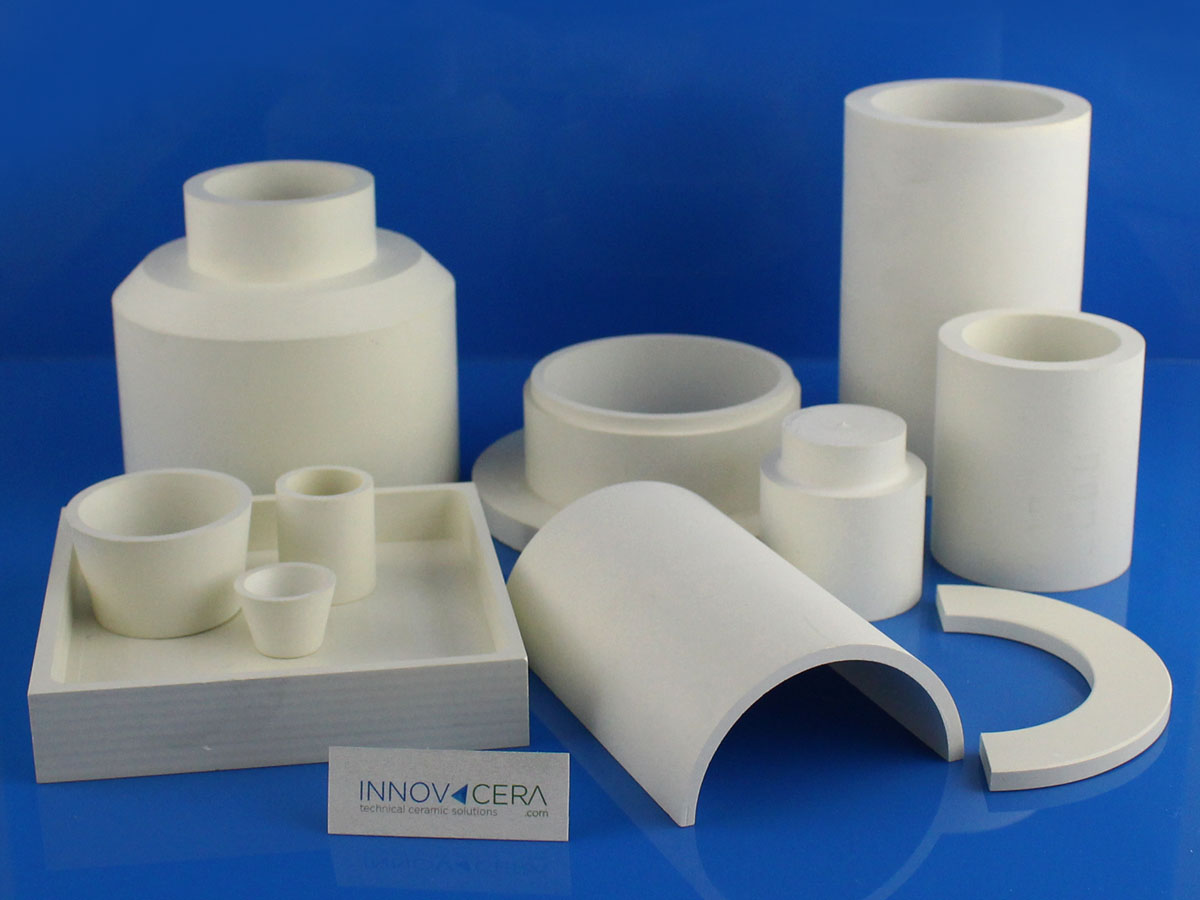

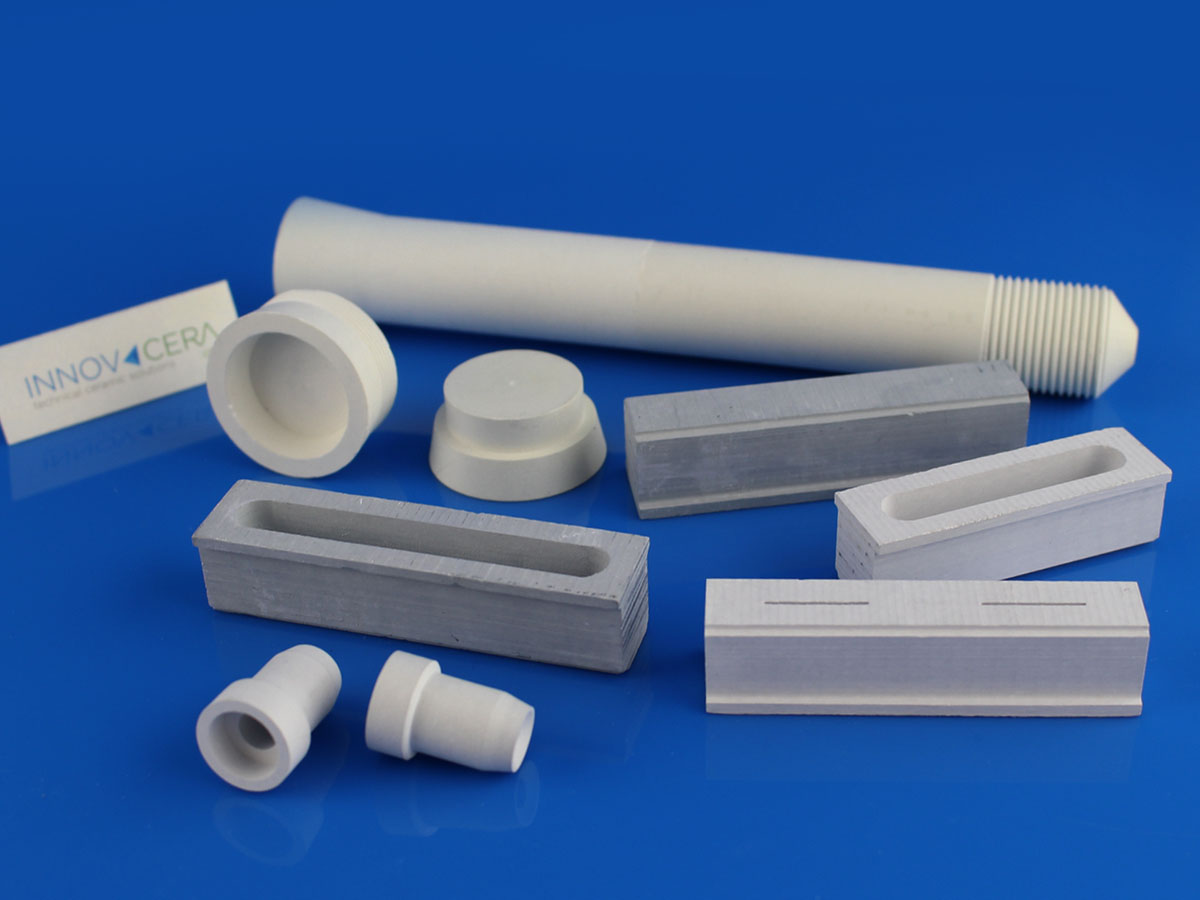

Boron nitride ceramic heater. The materials that can be used in advanced ceramic heaters include alumina al2o3 silicon nitride si3n4 beryllium oxide beo and aluminum nitride aln. Momentive boralectric r heaters made of unique combination of a dielectric ceramic material pyrolytic boron nitride and an electrical conductive material pyrolytic graphite. The boron nitride substrate heater is a vacuum process heater designed for processes wherein mostly non reactive gases are used. Alumina ceramic heaters are produced by implementing unique metallization and ceramic lamination processes.

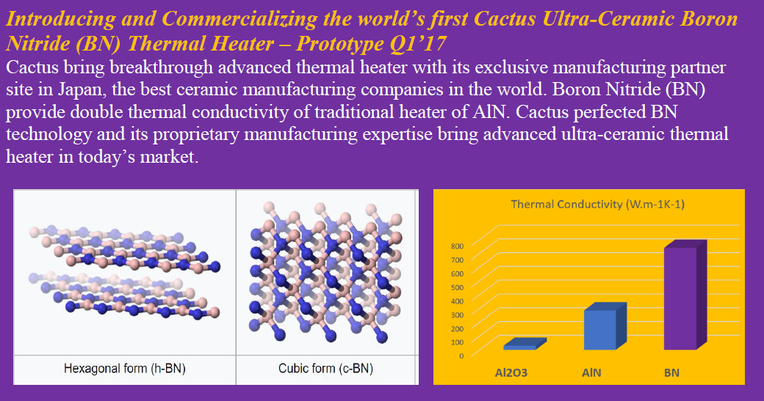

Both our pbn heater pyrolytic boron nitride and pg heater pyrolytic graphite are manufactured by high temperature cvd. Hexagonal boron nitride has a microstructure similar to that of graphite. Cactus ultra ceramic boron nitride thermal heater. Dependends on different requirements of applications the pg heating element could be covered by pbn again or just stay open.

Thus boron nitride ceramic product is an ideal choice in a wide range of industries such as. Pyrolytic graphite pg is placed on the surface of pbn plates by cvd method as conductor and heater. These heaters offer a robust solution for hv and uhv systems to heat substrates quickly to high temperatures. The hexagonal form corresponding to graphite is the most stable and soft among bn polymorphs and is therefore used as a lubricant and an additive to cosmetic products.

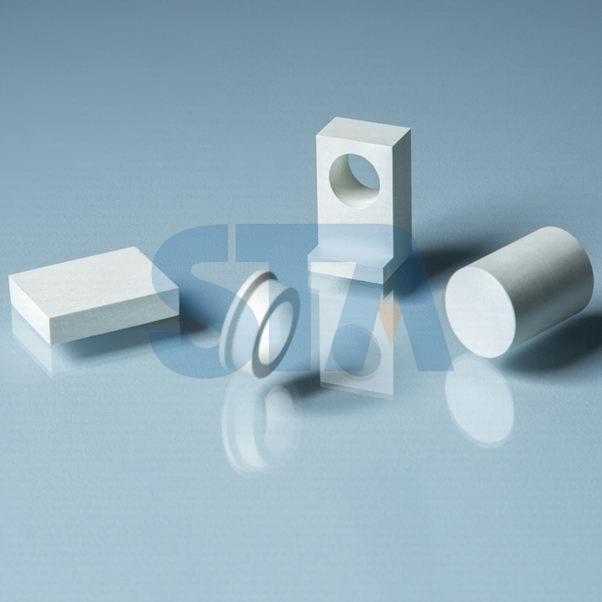

Boron nitride ceramic from advanced ceramic materials can withstand high temperature in high vacuum environment plus it has excellent corrosion resistance and electrical resistance. Boron nitride bn thermal heater with the highest power density 300 w cm 2 and ramp up rate 500c s. These high performance elements exhibit outstanding thermal properties. Ceramic has a high dielectric.

Although hpbn is an insulator with outstanding properties in temperature dielectric constant thermal shock. In both materials this str ceramics processing. Boron nitride is a thermally and chemically resistant refractory compound of boron and nitrogen with the chemical formula bn it exists in various crystalline forms that are isoelectronic to a similarly structured carbon lattice. Several variations of the boron nitride heater are available.

High purity and high performance pyrolytic boron nitride is used as the substrate for the pbn heating element. These heating modules are built to hold heat cool rotate and bias samples and wafers as a cost effective tool for leading edge research and development. Boron nitride ceramics can be offered in many forms including powder paint paste aerosol and in hot pressed solid form along with pyrolytic boron nitride pbn a chemical vapour deposition material.