Boron Carbide Ceramic Ppt

We use many ways and equipment to inspect for our b4c ceramic products.

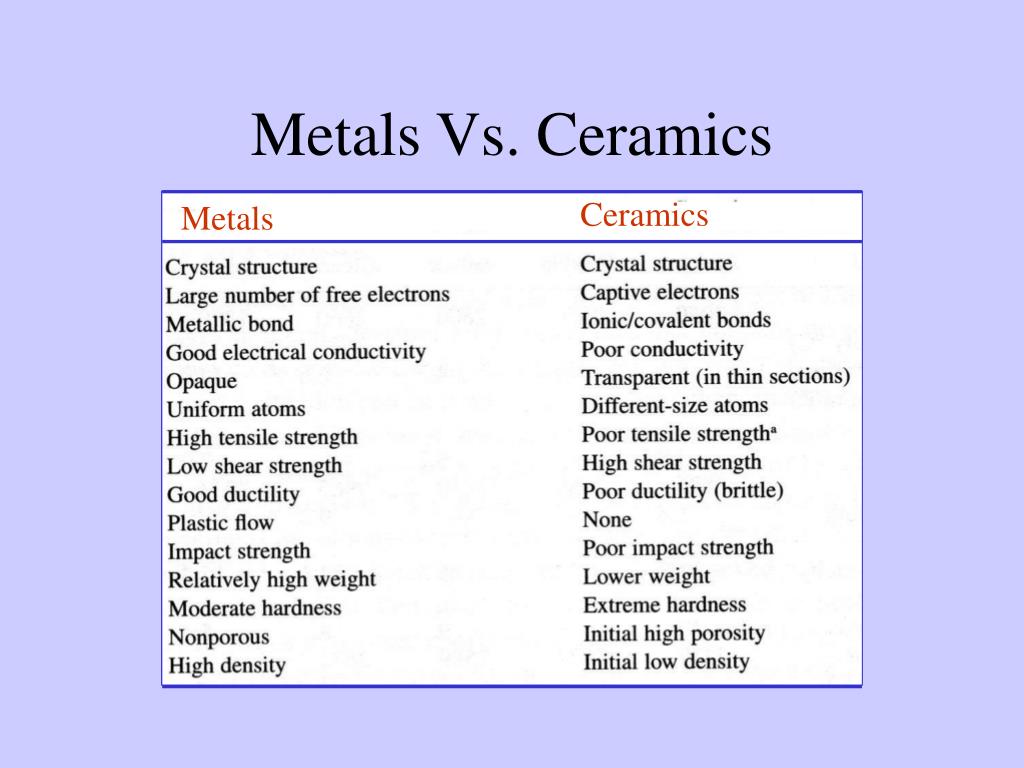

Boron carbide ceramic ppt. Utilized as a reinforcing agent for aluminum in military armor and high performance bicycles for more visit minerals and chemicals. Inorganic nonmetallic materials that consist of metallic and nonmetallic elements bonded together primarily by ionic and or covalent bonds its chemical compositions vary considerably from simple compounds to mixtures of many complex phases bonded together. High hardness is about hv3300 low density is about 2 5g cm3 boron carbide bullet proof ceramic is much better than silicon carbide and aluminum oxide material. The constant quality control for boron carbide ceramic during manufacturing is the guarantee for the good quality and for the satisfaction of our customer.

The current state of the art the monolithic multi curved boron carbide armor ceramic tile was developed by scientists at the us army natick research and development laboratories and picatinny arsenal in 1965. 2003 performed experiments for the ballistic impact on a boron carbide plate and they found that the loss of impact resistance of boron carbide is due to the phase. What are ceramic materials. It is perhaps the hardest of materials which can be processed as a conventional ceramic and its applications are concentrated where hardness is the principal requirement including grit blasting nozzles bearings.

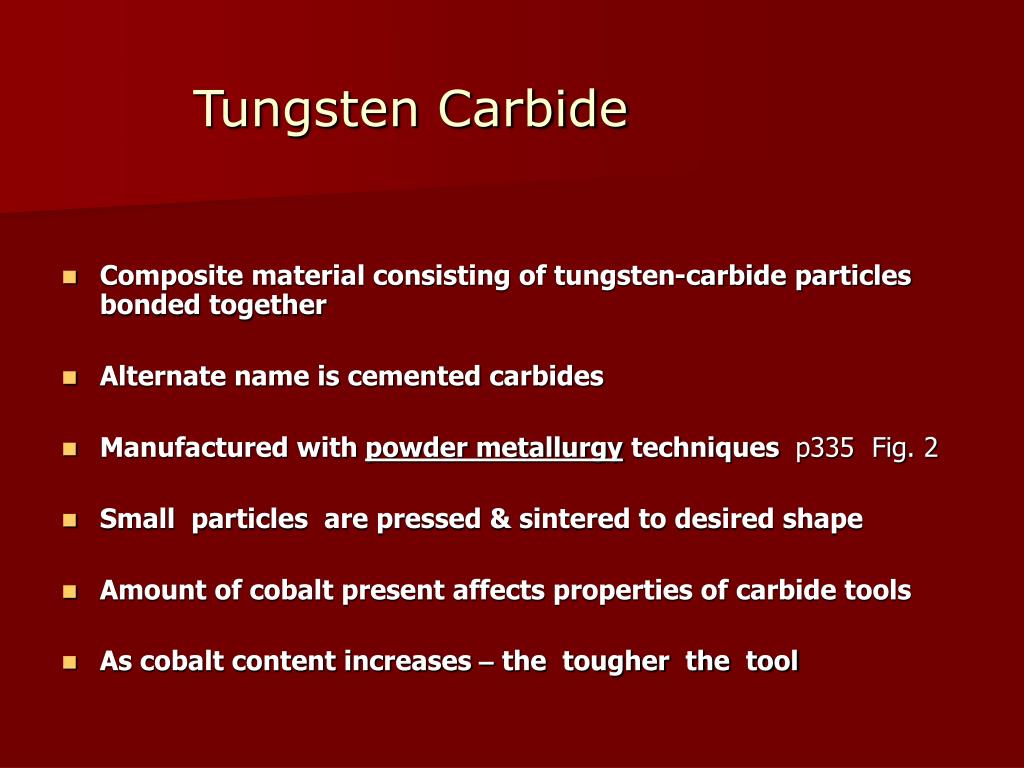

Alumina al2o3 boron carbide b4c silicon carbide sic and titanium diboride tib2. Meeting the specifications and drawings of our customers are the basis of our quality control. Low thermal conductivity and a high thermoelectric power light weight body armour thermocouple in combination with graphite. Boron carbide powder suppliers exporters it is an extremely hard synthetically produced material that is used in abrasive and wear resistant products it is used in powdered form in the lapping fine abrading of metal and ceramic products.

Ceramics used for engineering applications can be. Jayesh group is one of the leading manufacturer and supplier of boron carbide powder from india. Boron carbide covalent ceramic has a density of 2 52 g cm3 and a melting point of 2450 deg c. Shatter the incoming projectile energy absorbent material underneath ceramic armour is armor used by armored vehicles and in personal armor.

5 applications of boron carbide wear resistant components refractory industry. These innovations have brought. Boron carbide b 4 c is one of a number of boron carbon compounds but is the one most frequently used as a ceramic material. Lee and yoo 2001 conducted an analysis of a ceramic metal armor system in which the strain rate effect was considered and the ballistic limits for different ceramic metal back plate ratios were derived.

B4c ceramic bullet proof plate is widely used in heavy armored protection in planes tanks ships and high class physical protection. Boron carbide is produced by reducing boron oxide with carbon at high temperatures in an electric furnace.