Bone Ceramic Scaffolds

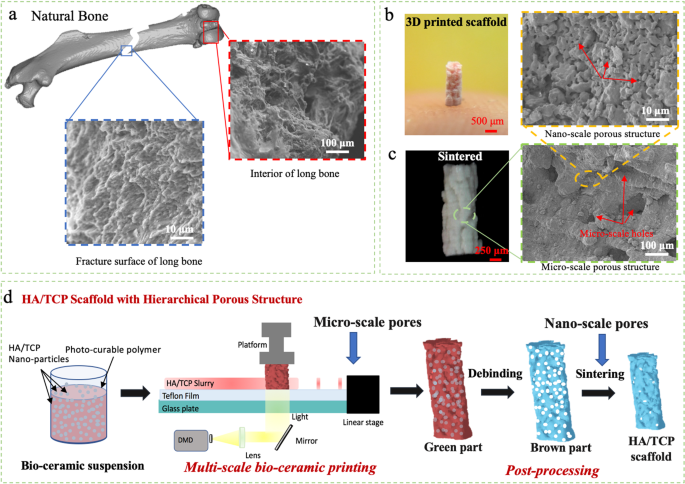

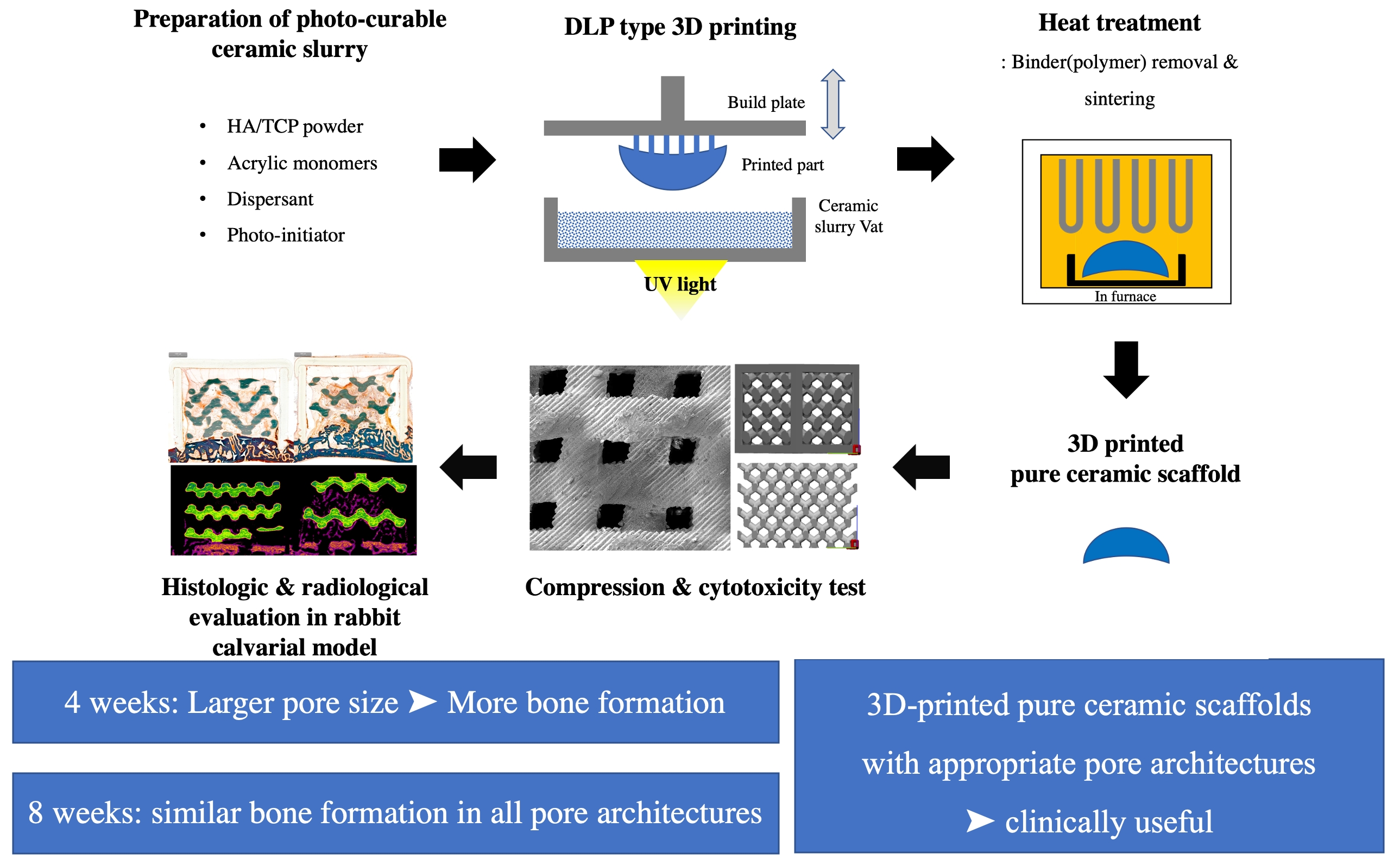

The proposed ha tcp scaffold without polymers obtained using the dlp type 3d printing system can be applied for bone regeneration.

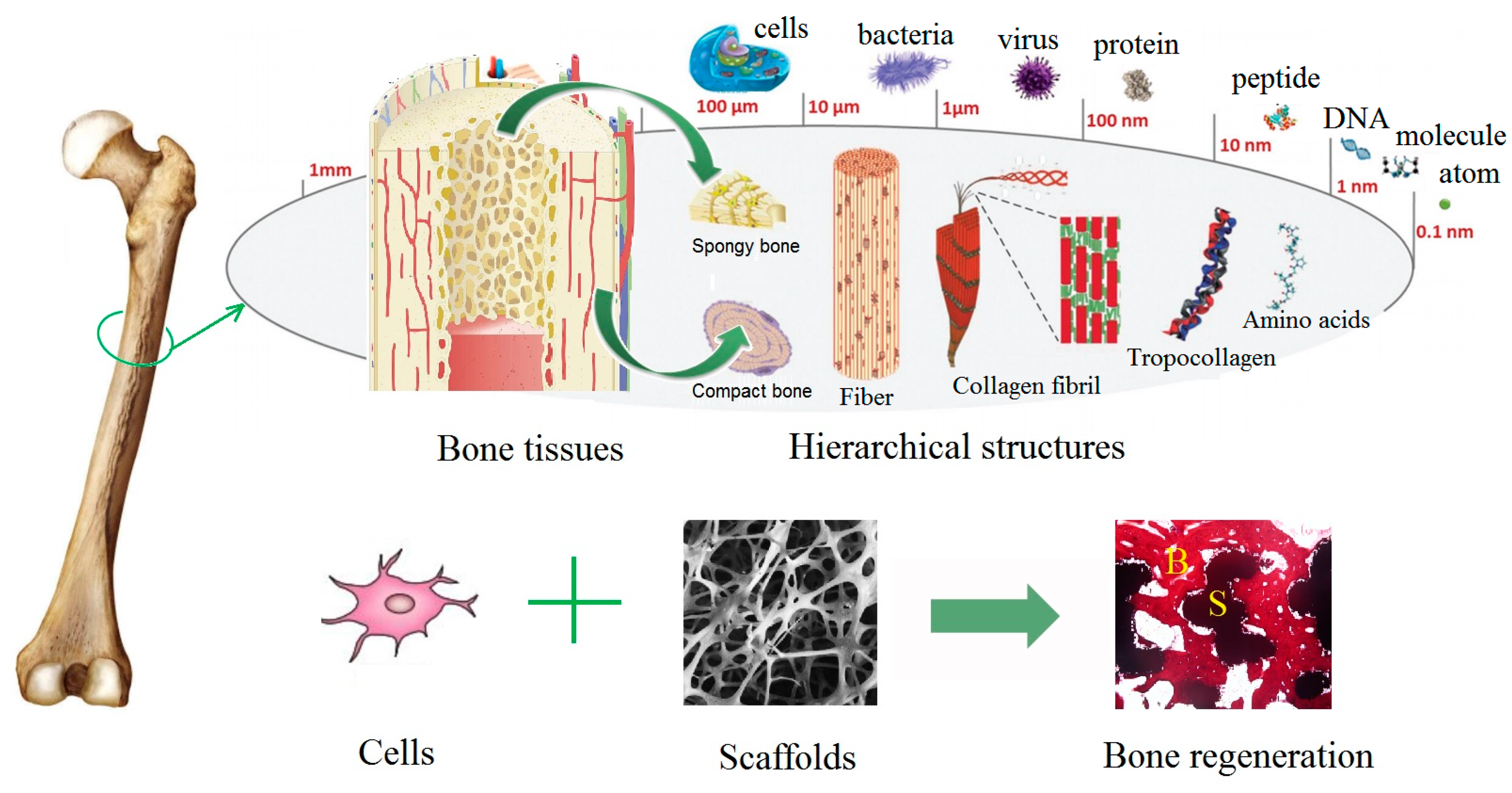

Bone ceramic scaffolds. Ceramic scaffold architecture has long been explored as a factor to optimize for bone tissue engineering. The porous scaffolds provide a three dimensional 3d structure for osteogenic cell adhesion proliferation and secretion of extracellular matrices to guide neo tissue growth 1. The proposed ha tcp scaffold without polymers obtained using the dlp type 3d printing system can be applied for bone regeneration. Bone regenerative medicine has emerged as a promising strategy for repair of damaged or diseased bone tissues.

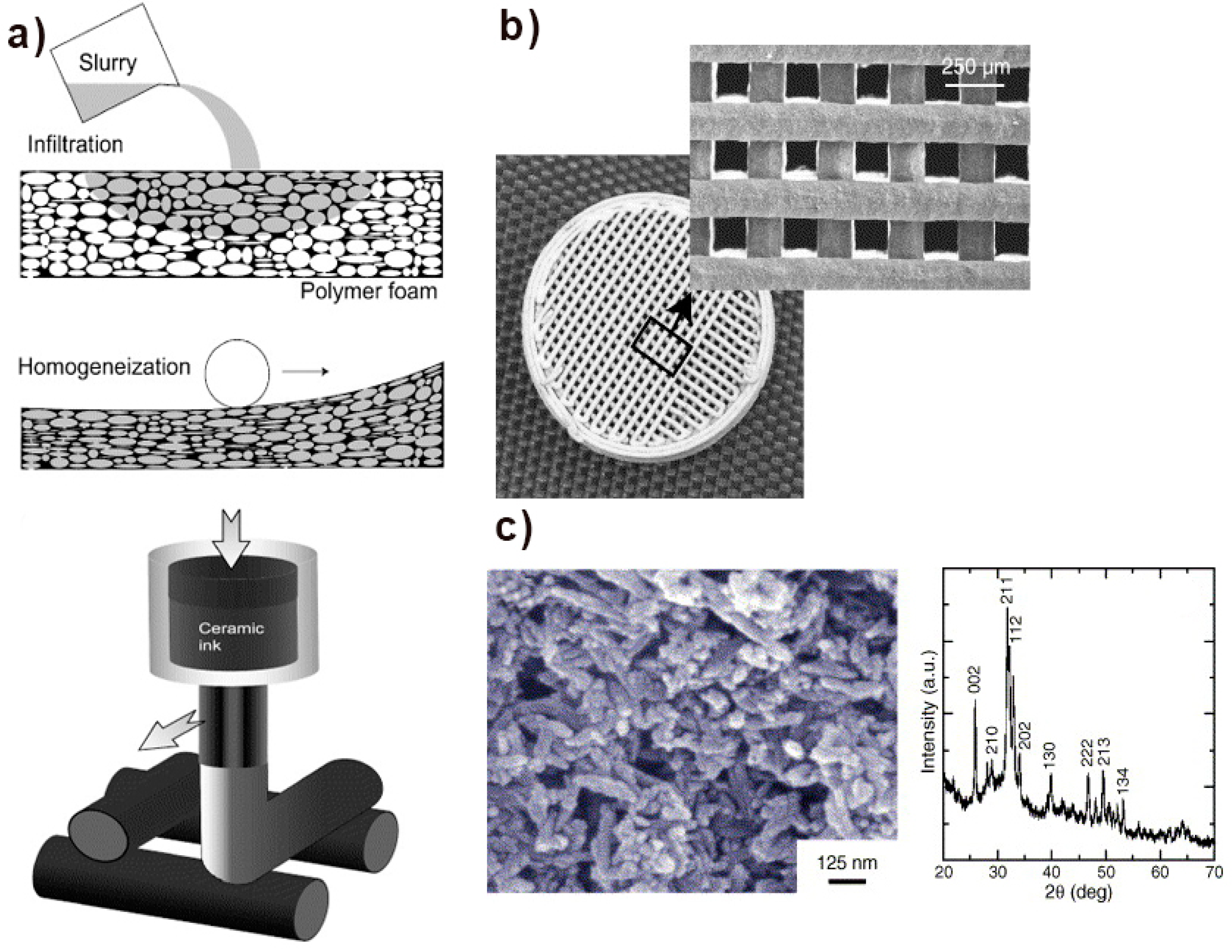

A surface morphology of tcp ceramic scaffold after immersing in sbf. 3d printed bioceramics have broad application prospects in bone. For many applications especially in the area of bone tissue engineering this scaffold will be fabricated from an inorganic ceramic or glass. While architecture has been shown to affect scaffold performance and biological response a single optimal scaffold architecture does not exist bohner et al 2011.

The development and challenges of bioactive ceramics are also discussed from the perspective of bone repair and regeneration. Thus organic inorganic composite scaffold materials have been the focus of recent research efforts. Considering chemical compositions bioceramic scaffolds e g calcium phosphate ceramics calcium silicate cs ceramics and bioactive glasses bgs are attracting increasing attention for use in bone tissue regeneration owing to their similarity to native bone inorganic components biocompatibility hydrophilicity bioactivity osteoconductivity and osteoinductivity. 3d printed porous ceramic scaffolds have obvious advantages such as enhancement of the controllability of the structure or improvement of the production efficiency.

The 3d printing of a ha tcp scaffold without polymers can be used for fabricating customized bone grafting substitutes. More sophisticated scaffolds were fabricated by 3d printing technology. Gelatin scaffold with varying glass ceramic content was fabricated using lyophilization technique.